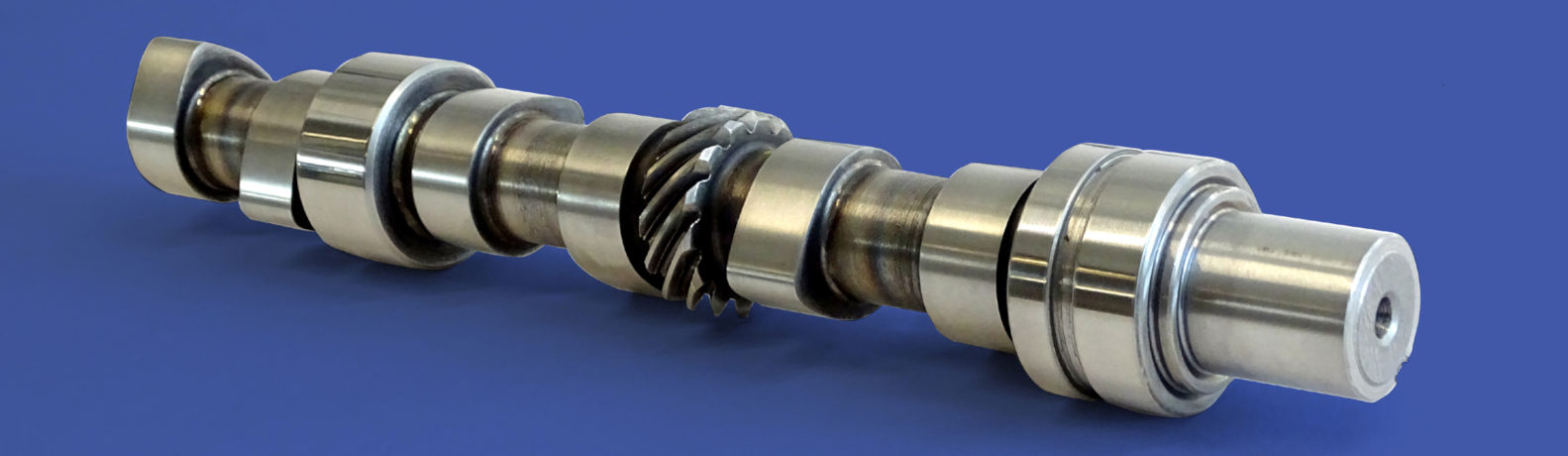

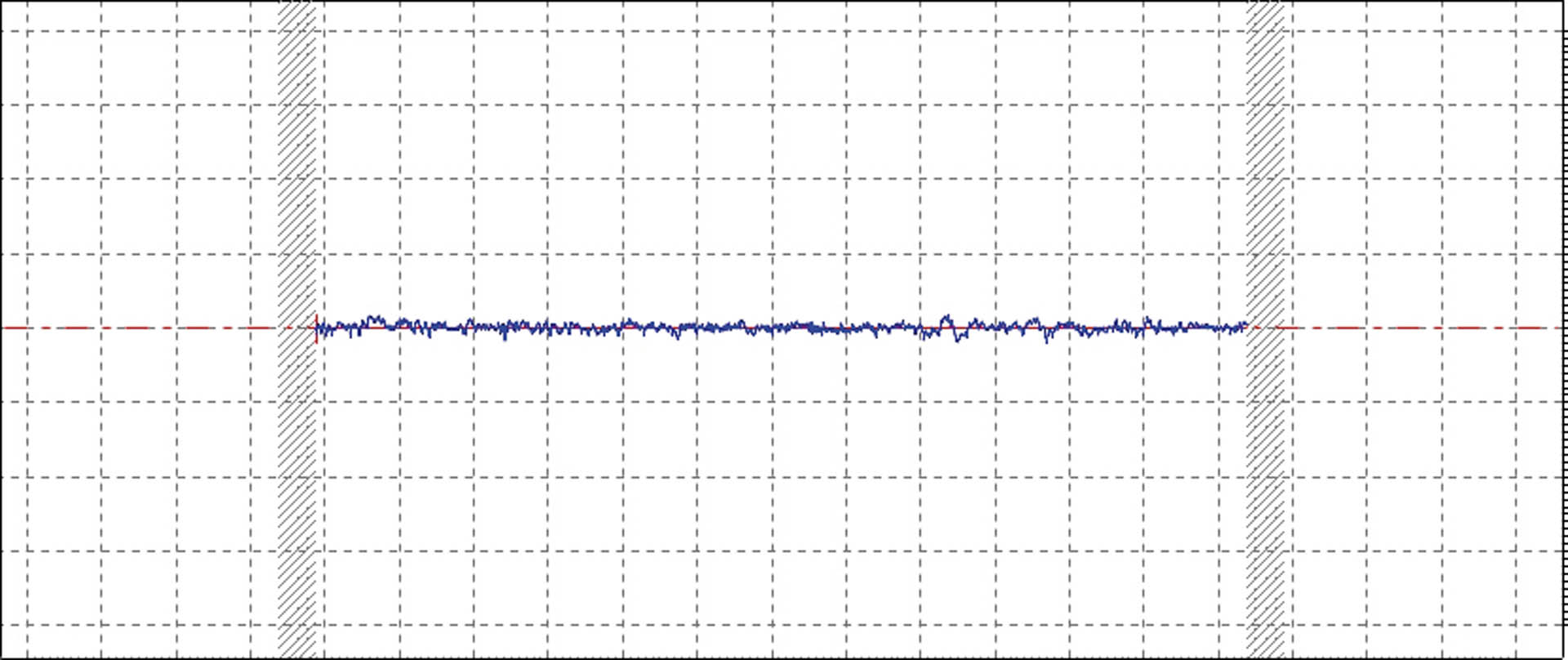

The highest level of component precision is a prerequisite for better performance, higher operational readiness, longer service intervals and efficiency with regard to the use of energy and raw materials. Performance is greatly improved by the optimal level of surface quality and shape tolerances. This is where the Microfinish process comes into play, which is also known as Superfinish, Finishing or Short Stroke Honing.

Microfinish technology

Why Microfinish / Superfinish?

The optimal micro-geometric and macro-geometric peak-to-valley height for your application

There is a global trend towards vehicles and engines with ever-improved fuel utilisation. Higher revolutions and increased compression generate an increasing level of stress for numerous elements. Therefore, the most advanced design requires a production process in which all the requirements stated by designers can be fulfilled. This is where precision machining comes into play, which enables optimal peak-to-valley height to be achieved for each specific application. Refined enough to avoid premature wear and tear, but rough enough to ensure the reliable lubrication of crankshaft bearings, for example.

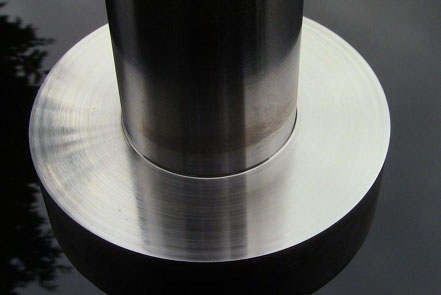

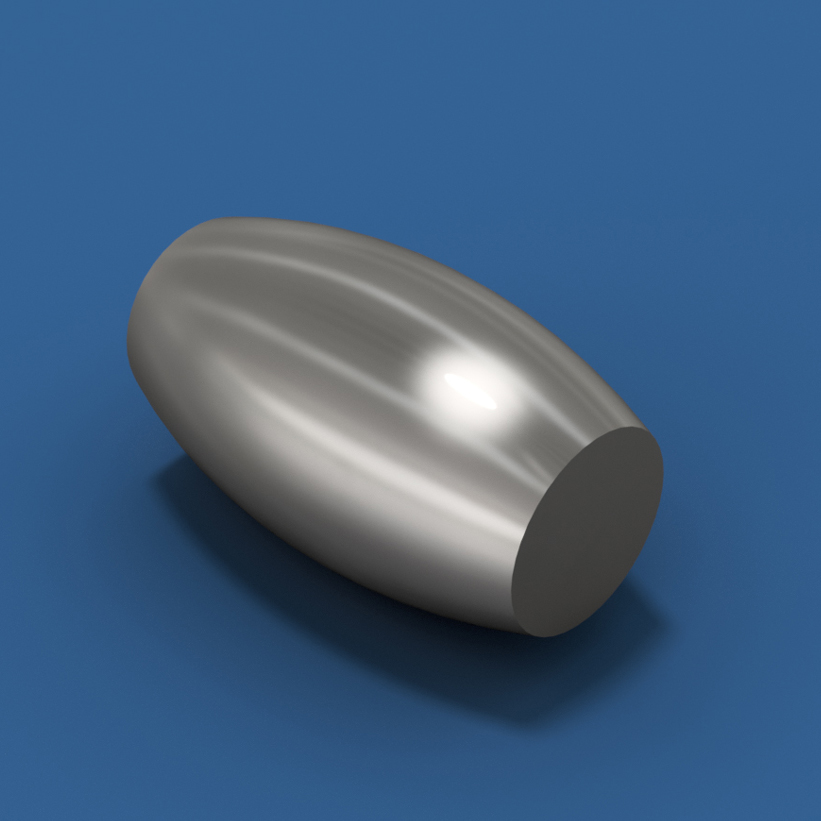

Highly durable and completely true surfaces

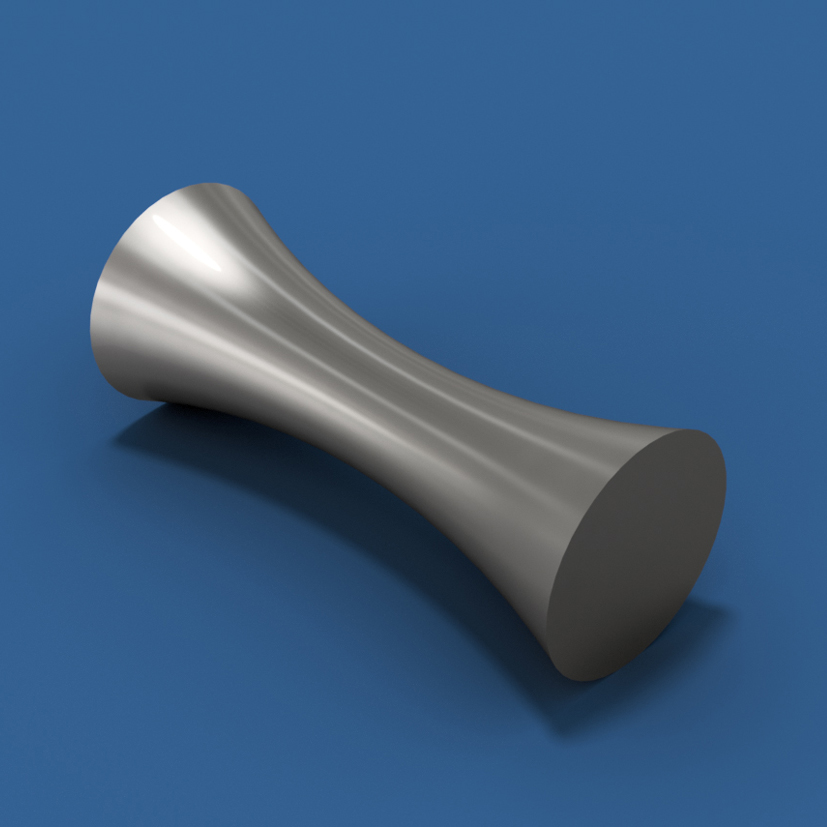

The considerations for spherical surfaces are the same as those for cylindrical surfaces. The least amount of shape deviation is a top priority in this area, in addition to the highest degree of surface quality.

Superfinish – the technology of the future

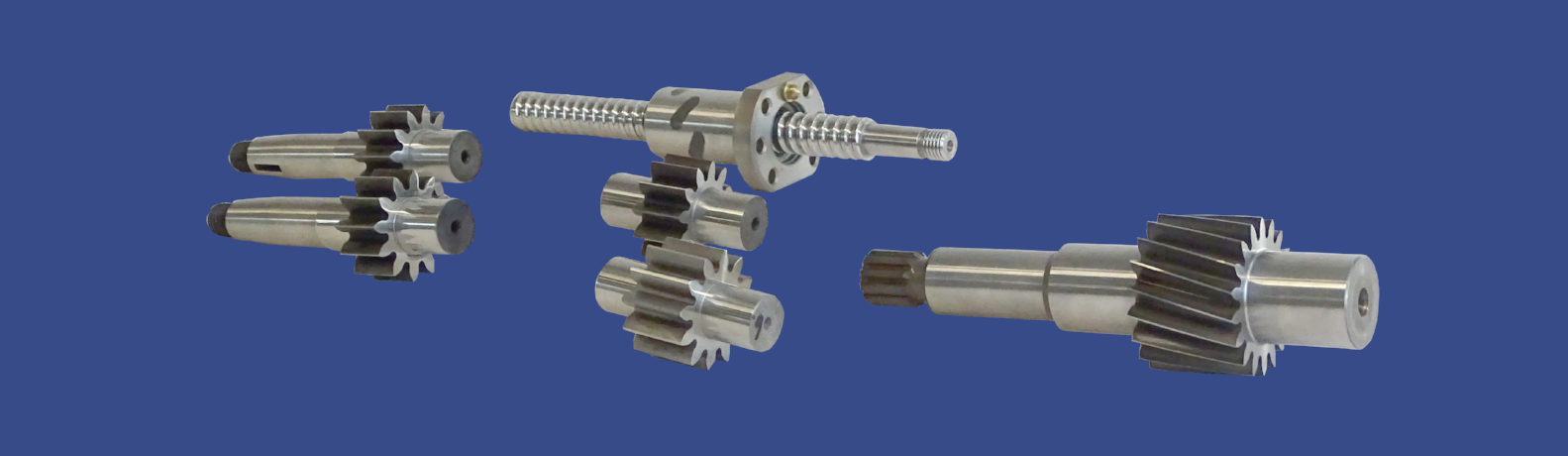

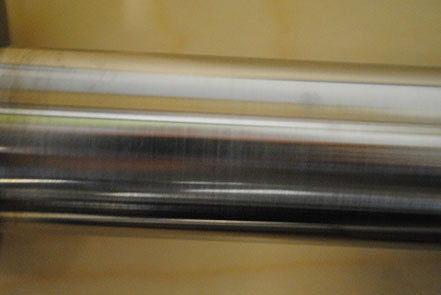

Refine your work surfaces with our tape finishing technology. The optimised surface generates less friction and thus improves durability and noise emission while simultaneously reducing energy consumption and wear. This type of surface improvement is simple, reliable and economical compared to other processes.

Thielenhaus Superfinish Innovation AG deals exclusively with finishing and surface technologies. We can draw on our many years’ experience in this field to solve even the most challenging finishing tasks for our customers using our expertise from R&D alongside practical implementation.

Surface qualities that can be influenced by microfinishing

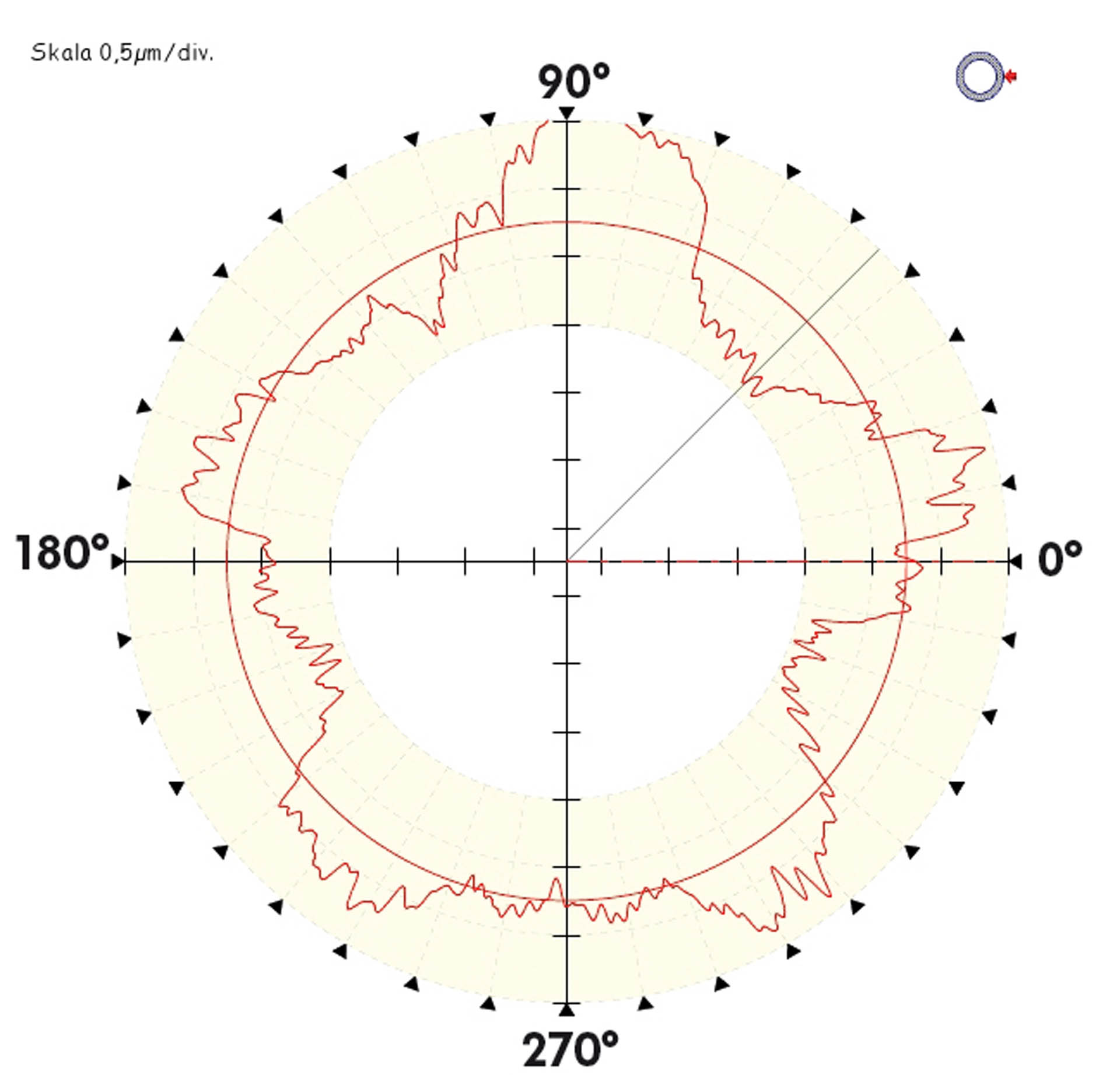

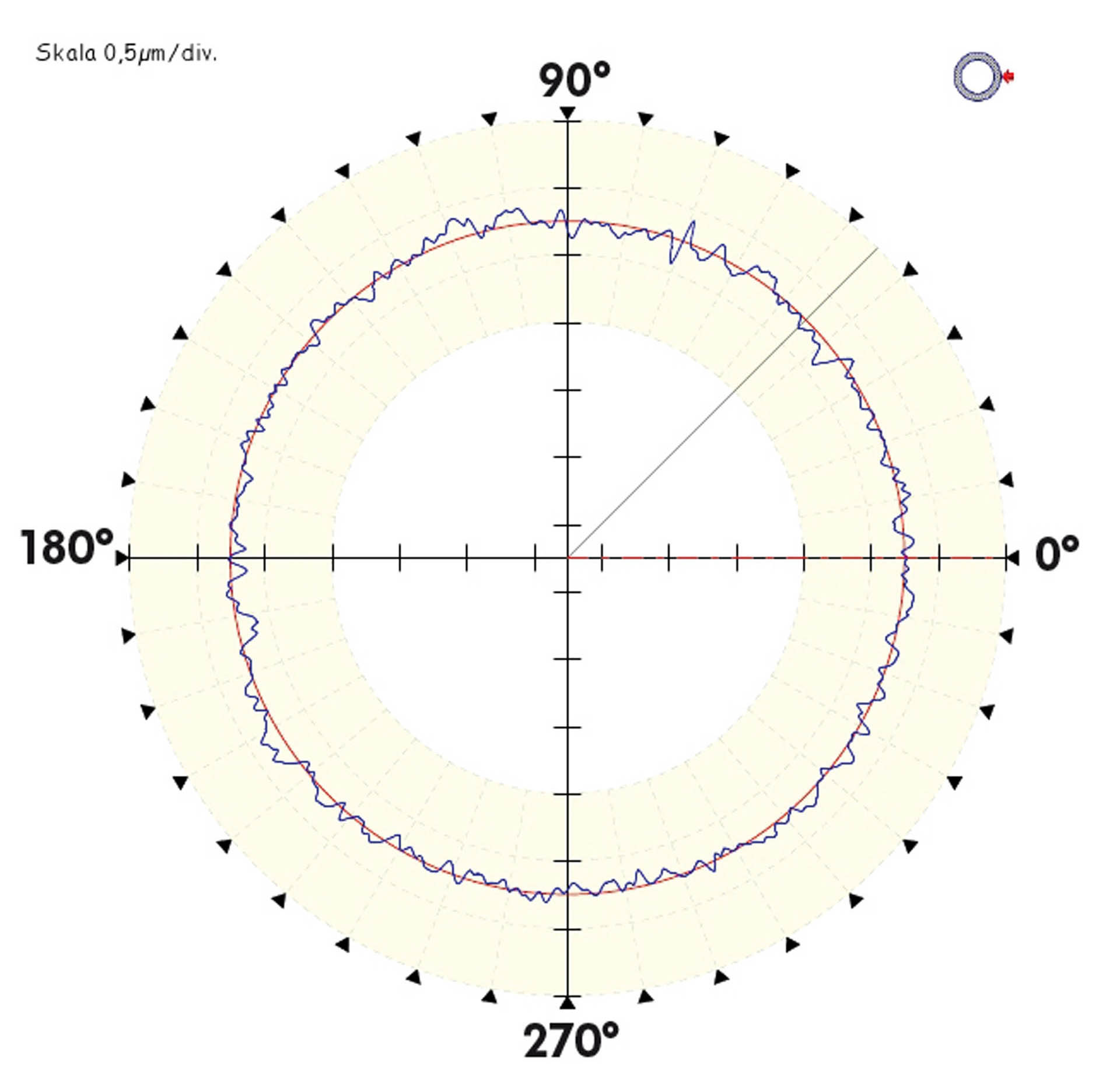

- Roundness

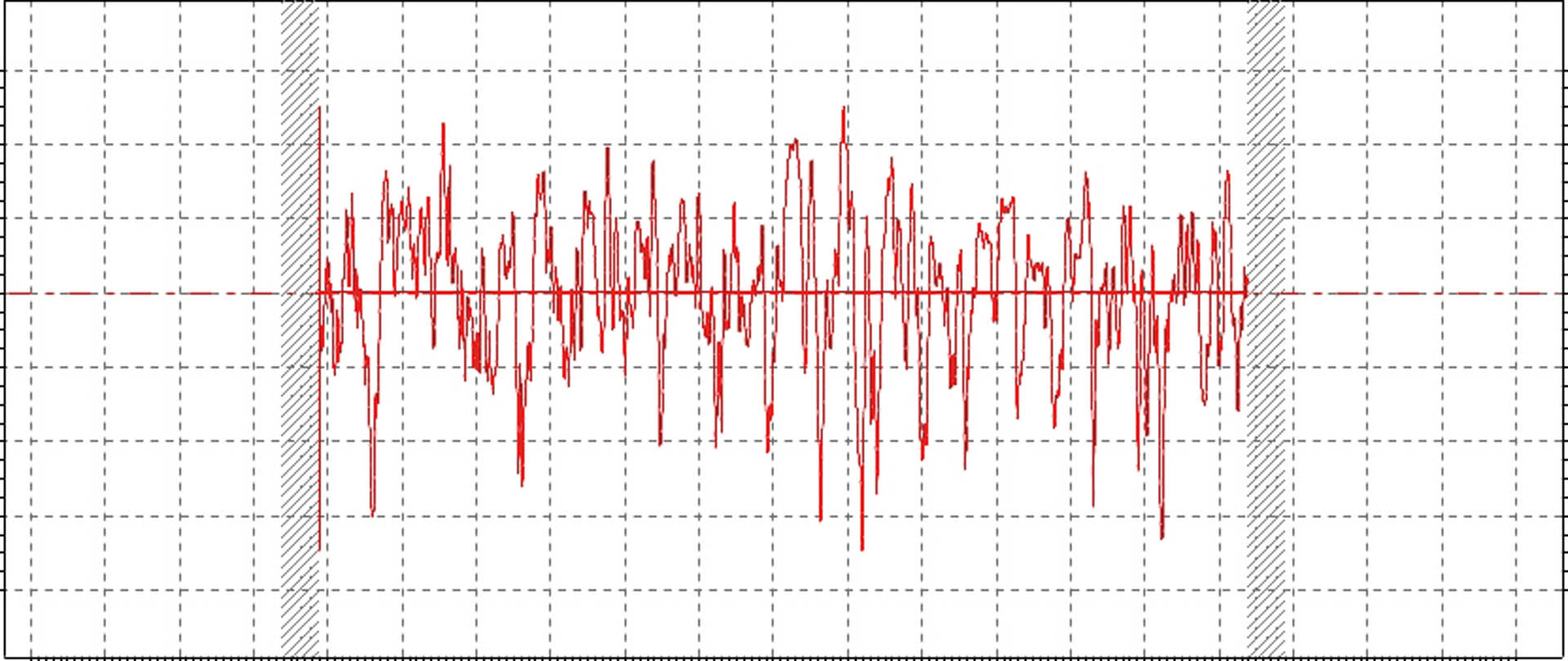

- Roughness

- Waviness

- Straightness

- Cylindricity

- Parallelism

Surface structures that can be created with Microfinish

- cross-hatch grinding

- twist-free

- radial rotation

- circular

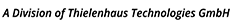

Workpiece shapes that can be machined with Microfinish

spherical

domed

conical

cylindrical