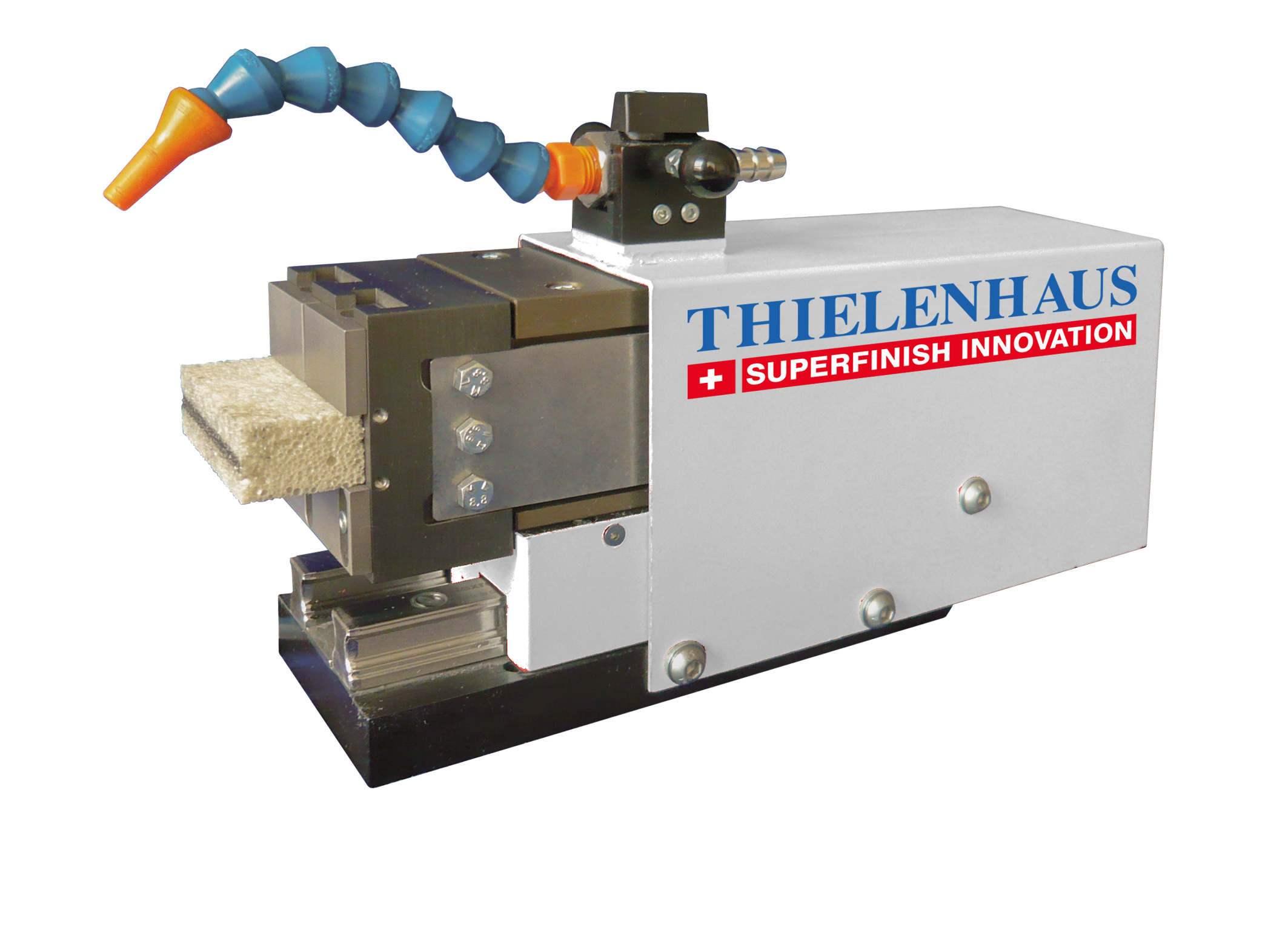

Microfinish-Aufsatzgeräte (2)

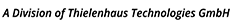

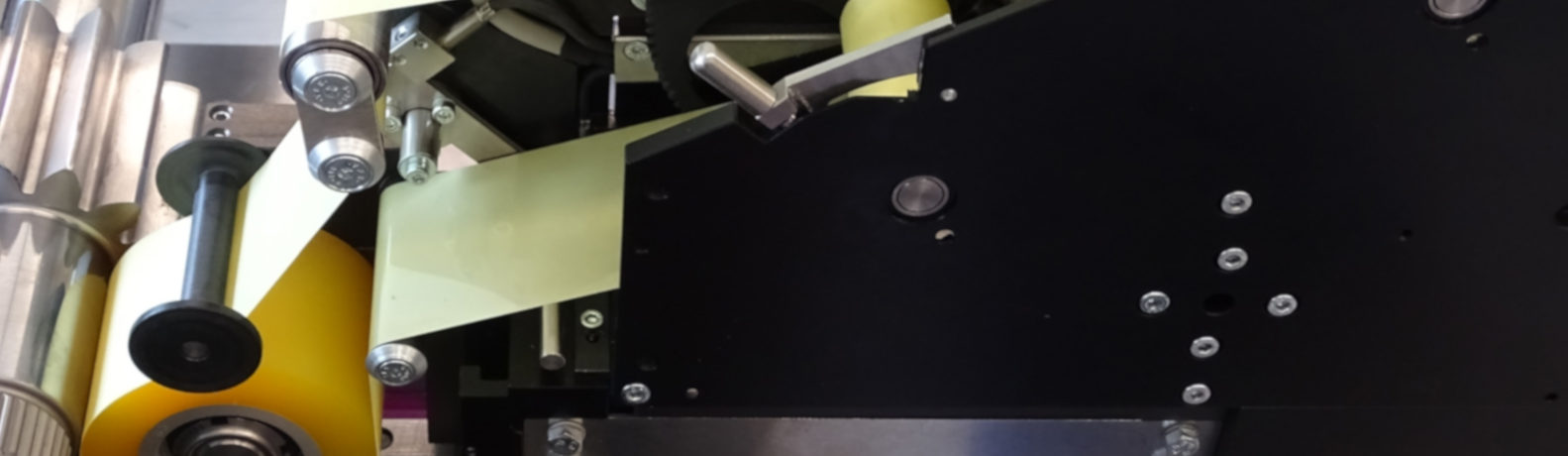

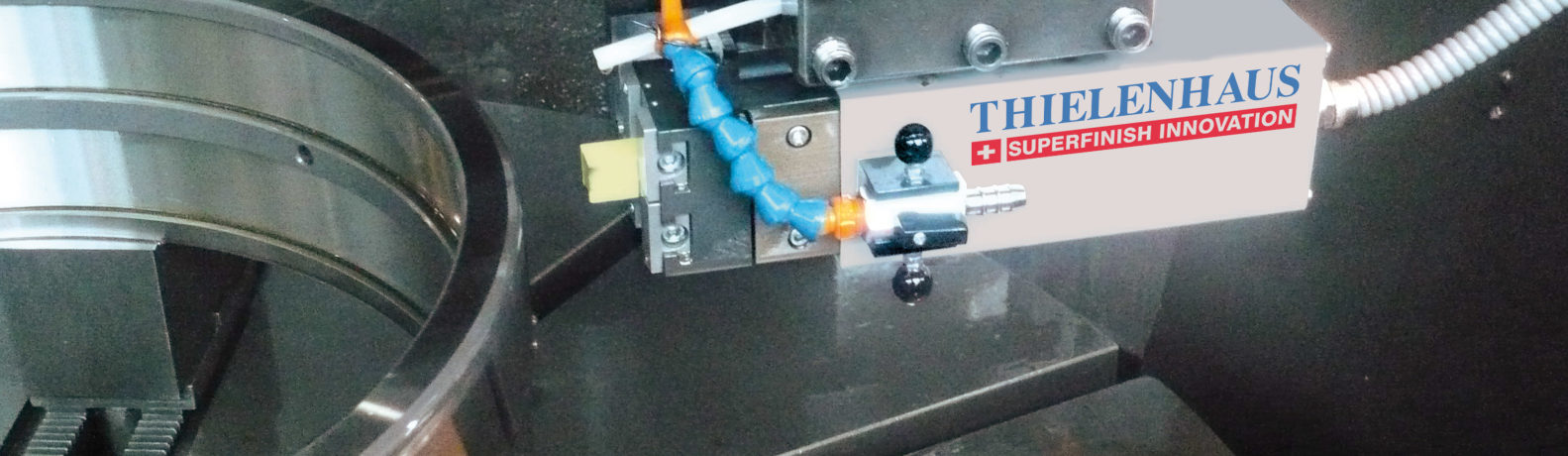

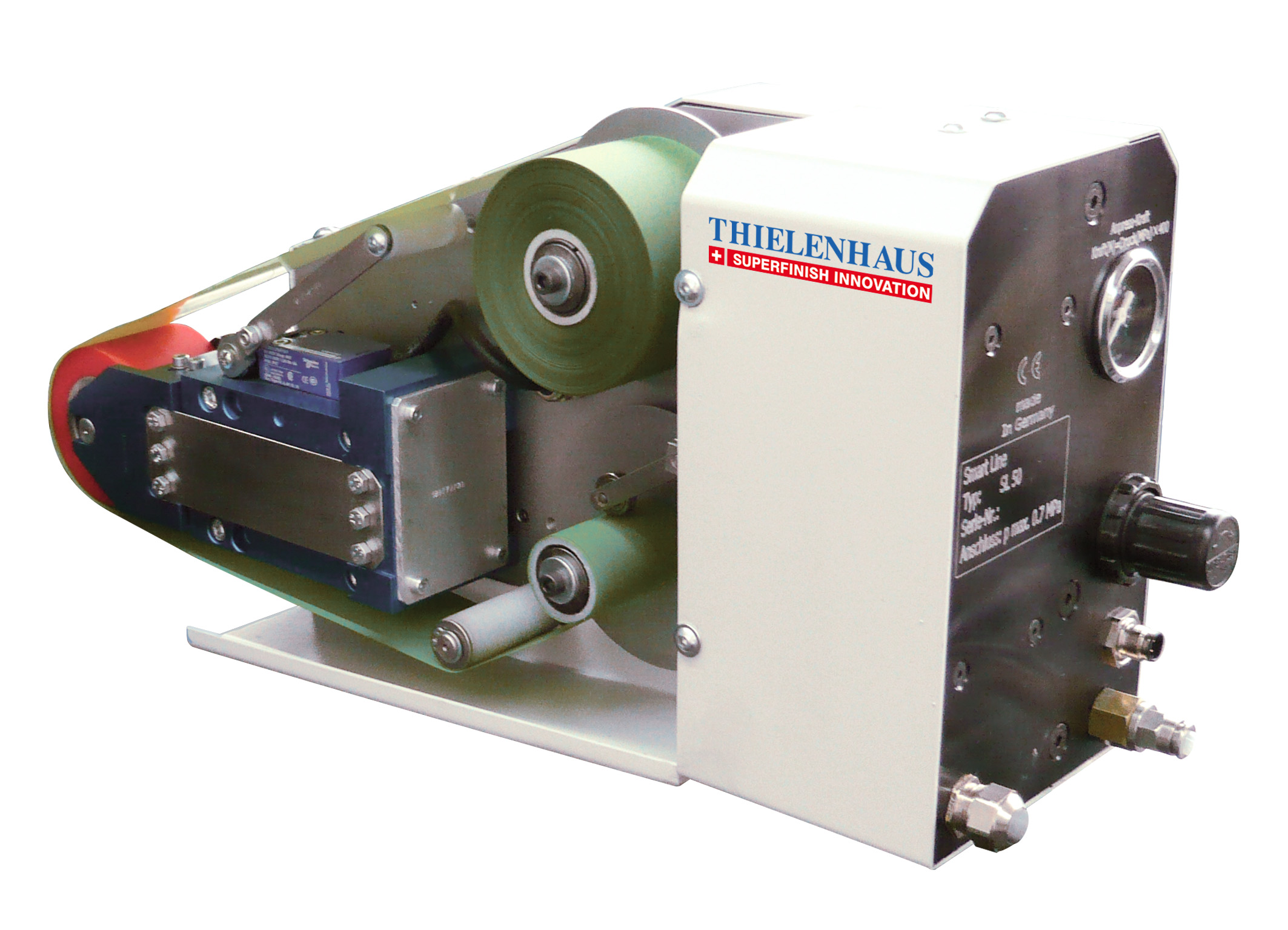

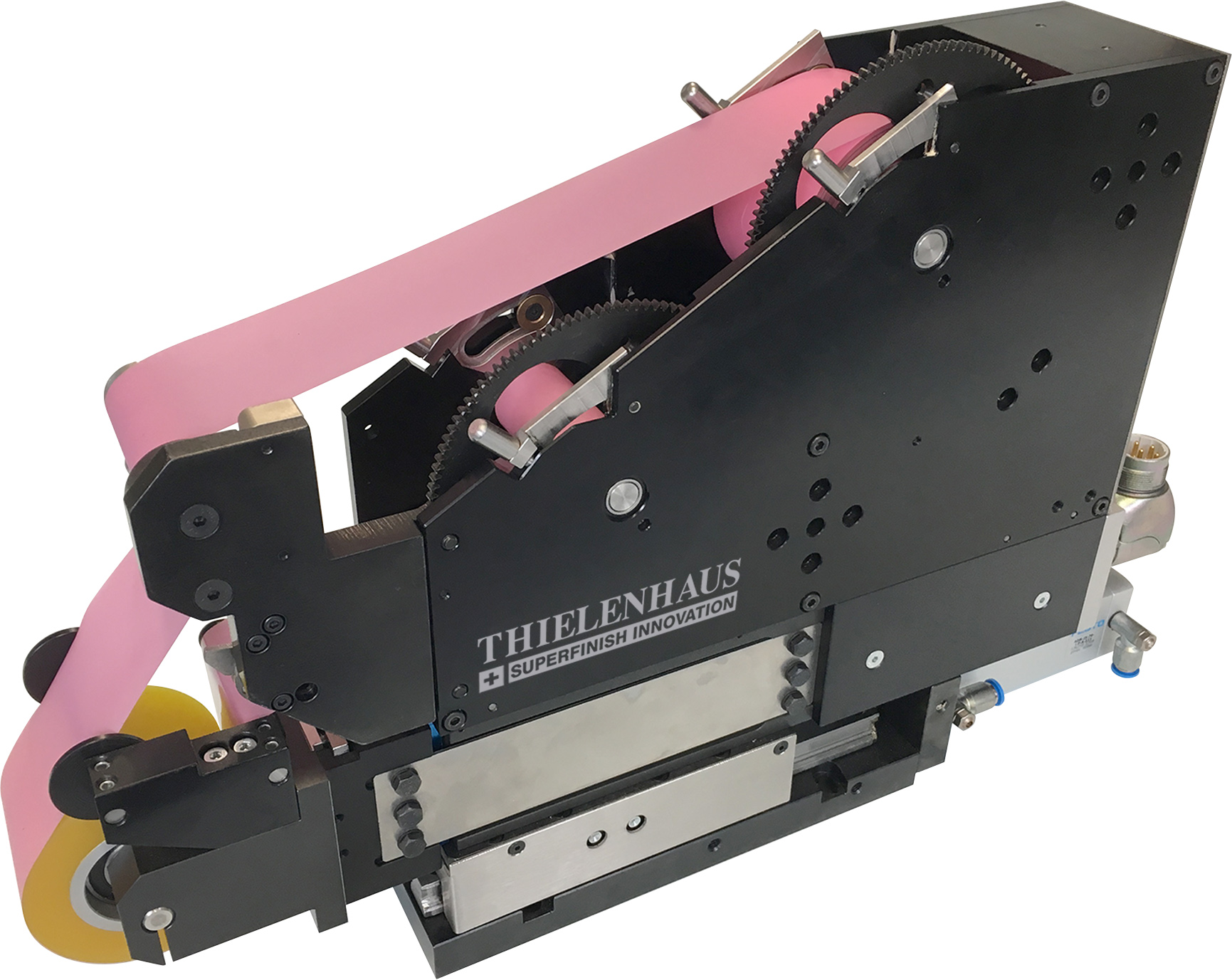

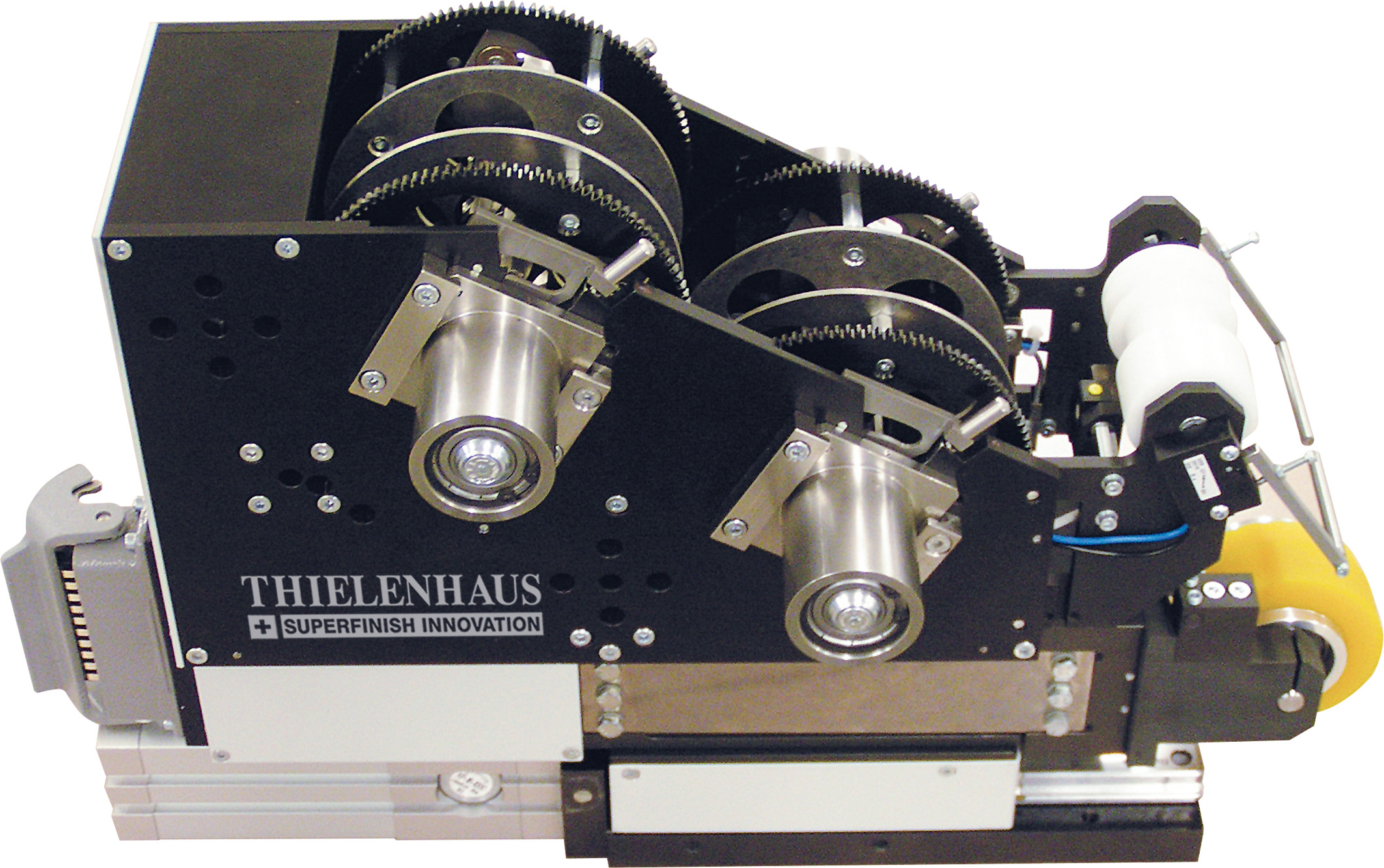

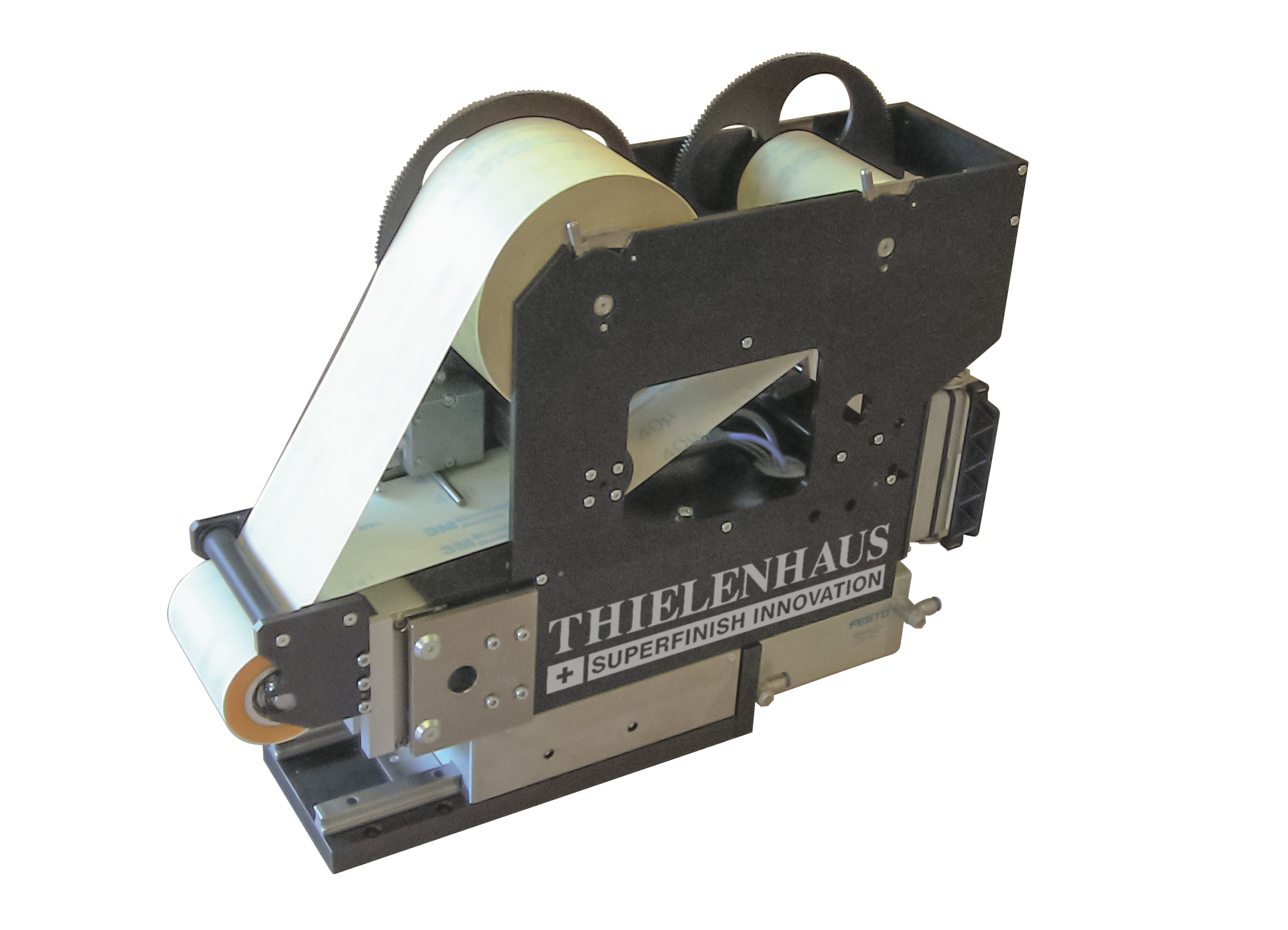

The workpiece is rotated, and the attachment device is operated via the supporting machine, while the oscillation of the tool and the contact pressure are regulated by the control unit of the attachment device. Depending on the device, the oscillation frequency can be up to 2,000 double strokes per minute. All rotationally symmetrical workpieces of any hardness that can be fixed between spikes can be processed this way. Even big calendar rollers in the paper, textile and plastics industries can be finished with the devices in their installed state and thus reconditioned.

The optimised surface generates less friction and thus improves durability and noise emission while simultaneously reducing energy consumption and wear. This type of surface improvement is – compared to other processes – simple, reliable and economical.

For controlling the attachments, you can choose either the SBM manual control box for manual finishing of individual parts and small series or the SBA automatic control box for time-controlled puncture finishing of individual parts and small series.