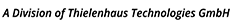

In virtually all technical fields, the requirements placed on the quality of individual components are increasing. As a result of this, surface-improving and geometry-improving superfinishing techniques are gaining importance. Today, even smaller suppliers must be capable of working to the finest tolerances in dimensional accuracy. For these applications or small batch sizes, Thielenhaus Microfinish presents various (in some cases) further developed attachments for carrier machines at the EMO 2017 in Hanover/Germany. The advantages of the microfinish process can therefore also be used on conventional turning, grinding or milling machines, so that the surface, roughness, waviness and contact area percentage of the workpieces can be improved in a manner that is reliable in terms of process.

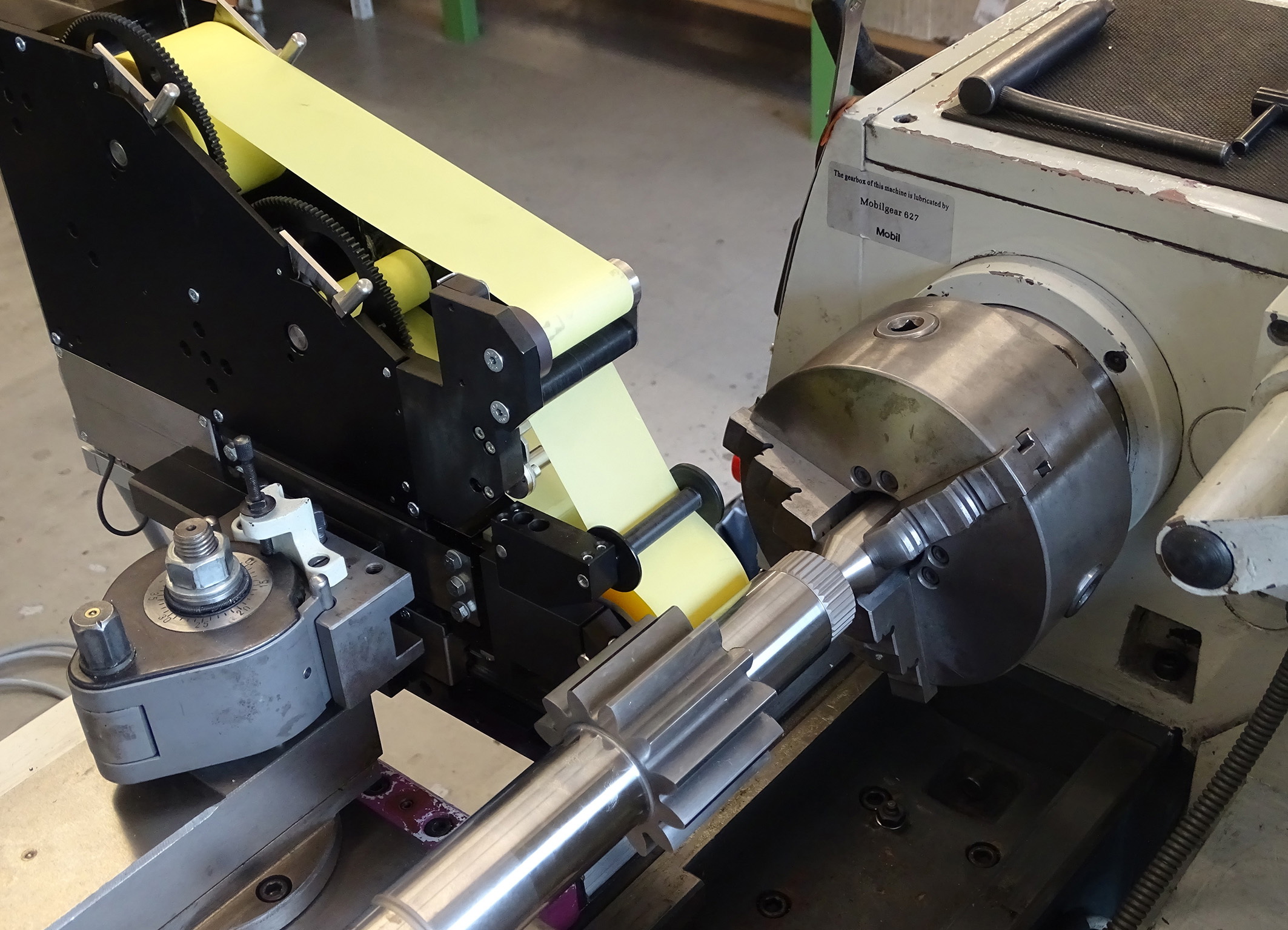

The new tape finish device KG50 S is equipped with servomotors, for example, and has a high oscillation frequency of 3,000 DH/min. Due to its modular construction, an adaptation to the stone finisher is even possible. Good accessibility makes it easier to change the tape. Due to the rotational independence of the workpiece, the device is also suitable for the machining of camshafts.

With the abrasion produced sinusoidally by means of the oscillation, the softening skin produced previously during hard turning or grinding is removed, and the roughness as well as the contact area percentage are decisively improved. This enables a surface roughness of Ra 0.01 μm to be achieved with rollers and Rz 0.3 μm with bearing surfaces. At the same time, the surface can be given a structure with defined, criss-crossing grooves to improve its tribological properties.

Even though they’re small and good value for money, the devices are nevertheless high-performance units geared towards three-shift operation. They are principally used for geometrical improvements in roundness, evenness and cylindrical forms. Surfaces can also be smoothed to a mirror finish and definable levels of roughness can be produced. The residual compressive stress can also be raised in order to make the surface more wear-resistant. As well as chamfering edges and smoothing joints, the attachments can be used to achieve visual, cosmetic surface textures.

Microfinish attachments are particularly suited to the small batch sizes typically found in the production of hydraulics rods, components, sealing seats and shaft sleeves. However, larger individual workpieces such as calender rolls, cold rolls, Sendzimir rolls and printing rolls can be worked to a mirror finish. The competitively priced attachments are ideal for use wherever precisely defined and structured surfaces are required for small batch sizes.

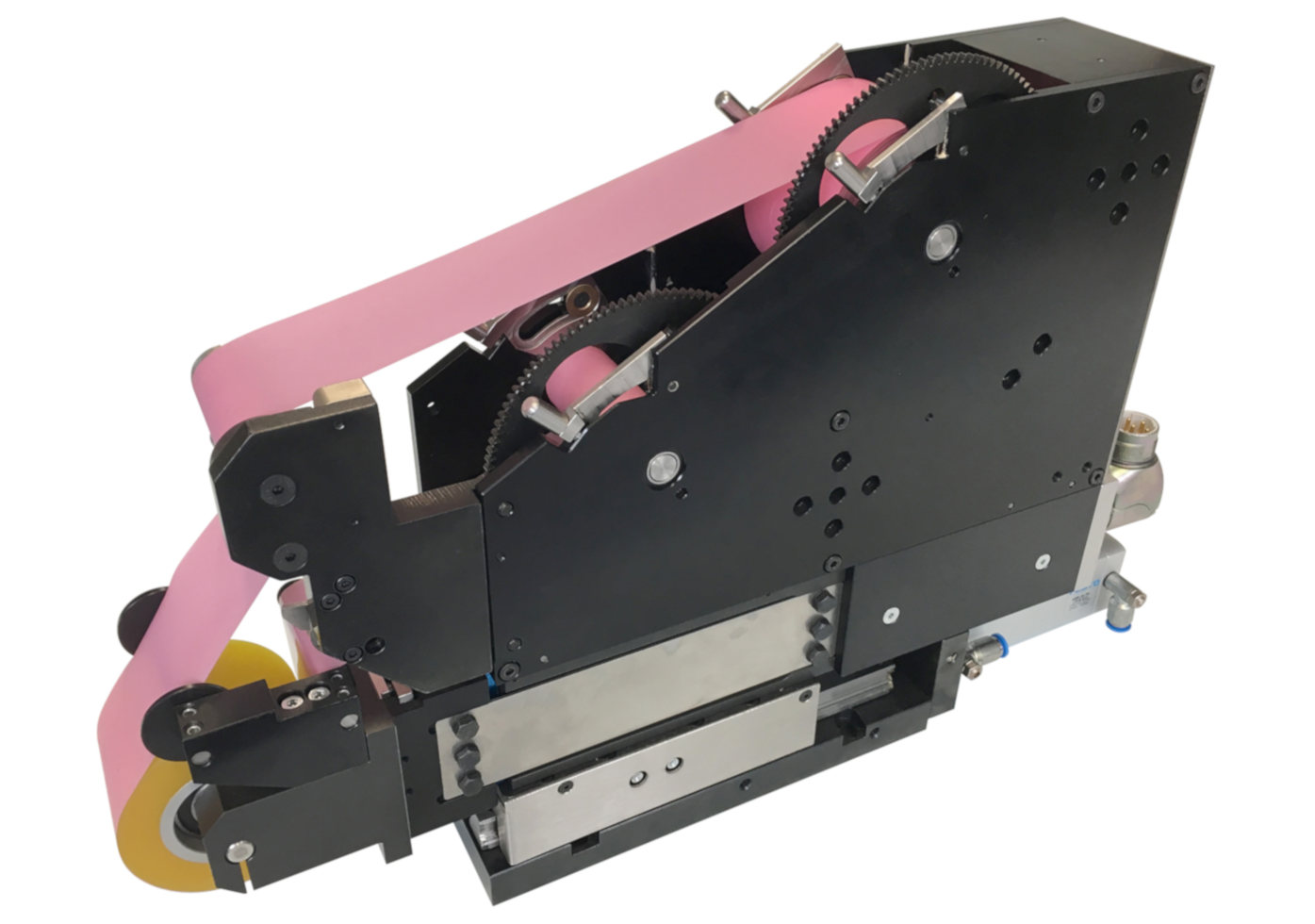

Since the attachments can be used with many different base machines and special equipment, the workpieces are not dimensionally limited. Their form can be that of a flat surface, start-up shelves, external or internal rotationally symmetrical surfaces, but it can also be that of excenters, cams or cam discs. Further uses also include those involving spherical surfaces such as radii and undercuts.

|

|

|

| Thielenhaus Microfinish’s attachments represent a cost-efficient opportunity to machine small batch sizes with finish tapes and stone tools using the base machines that you already own. | The new tape finish device KG50 S is equipped with servomotors and has a high oscillation frequency of 3,000 DH/min. It is possible to adapt the stone finisher. | Compact finishing device for creating spherical surfaces using a base machine. |